In today's highly competitive manufacturing industry, efficiency, precision, and speed are of utmost importance. It is essential for manufacturers to adopt the latest technology to improve their production processes and stay ahead of the competition. One of the most revolutionary technologies that have taken the manufacturing industry by storm is laser cutting machines.

Laser cutting machines have become an invaluable tool in metal fabrication, as they offer a range of benefits compared to traditional cutting methods. With their high precision, speed, and flexibility, laser cutting machines are a game-changer for manufacturers worldwide. They are used to cut a wide variety of materials, including steel, aluminum, stainless steel, copper, and brass, among others.

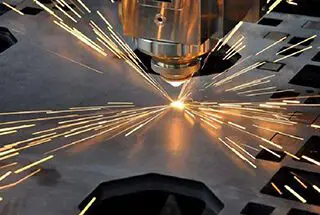

One of the biggest advantages of laser cutting machines over traditional cutting methods is their ability to cut through materials without much waste. Unlike traditional methods that use saw blades or other mechanical cutting tools, laser cutting machines use a highly focused beam of light to cut through the material. This results in cleaner, more precise cuts, with less scrap and waste material produced.

Another advantage of laser cutting machines is their speed. Laser cutters are capable of making cuts in seconds, while traditional cutting methods can take several minutes or hours to complete. This means that manufacturers can increase their production output, resulting in higher efficiency and reduced production time.

In addition to speed and precision, laser cutting machines also offer a high degree of flexibility. They can be programmed to cut complex shapes and designs, making them ideal for custom manufacturing jobs. This flexibility has opened up new opportunities for manufacturers to create unique and intricate designs that were previously impossible to produce using traditional cutting methods.

With the increasing demand for precision and performance in the manufacturing industry, laser cutting machines have become an essential tool for manufacturers across the globe. Whether it's cutting sheet metal, pipe, or tube, there is a laser cutting machine available to fit every need.

Sheet/plate laser cutting machines are used to cut flat sheet metal, including aluminum, stainless steel, carbon steel, and other metals. These machines are typically used for high-volume production and can handle large sheets of metal with ease. They offer high precision and speed, making them ideal for cutting intricate designs and patterns.

Tube/pipes laser cutting machines are specifically designed to cut tubes and pipes. These machines come in a range of sizes, from small desktop models to large industrial machines capable of handling large, thick-walled pipes. They offer high precision and speed, making them ideal for manufacturing pipes and tubes with intricate designs.

The latest addition to the laser cutting machine family is the fiber metal laser cutter. These machines are designed to cut a wide range of metals, including aluminum, copper, brass, and titanium, with exceptional precision and speed. They are widely used in the automotive, aerospace, and medical industries, among others, where precision and accuracy are crucial.

In conclusion, laser cutting machines have revolutionized the manufacturing industry, offering manufacturers greater flexibility, speed, and precision. With the wide variety of laser cutting machines available, manufacturers can choose the machine that best fits their needs and optimize their production processes. As technology continues to evolve, it is expected that laser cutting machines will become even more advanced, opening up new opportunities for manufacturers worldwide.