1. Technical Parameters

1. Technical Parameters | cnc plasma cutter for sale | ||

| No | Item | Standard Configuration |

| Model | YMLX-300*3000*8000 | |

| 1 | CNC control system | Shanghai Fangling F2300BX |

| 2 | THC | Shanghai Fangling F1621 |

| 3 | Console | YOMI |

| 4 | Clamping device | Three-jaw chuck |

| 5 | Longitudinal drive | Stepper motor |

| 6 | Y axis rotation axis drive | Stepper motor |

| 7 | Transfer method | Chuck drive |

| 8 | Precision reducer | High precision reducer |

| 9 | Arm system | YOMI |

| 10 | Support bracket | YOMI |

| 11 | Guide rail | Longitudinal 24KG T shape rail |

| 12 | Lifting device | Electric rack and pinion |

| 13 | Drag chain | Wear-resistant nylon chain |

| 14 | Cutting method | Plasma |

| 15 | Cutting material | Carbon steel/stainless steel |

| 16 | Plasma cutting thickness | 200A plasma power source |

| 17 | Flame cutting thickness | 150mm |

| 18 | Cutting pipe diameter | 50-300mm |

| 19 | Pipe cutting length | 3000mm |

| 20 | Plasma power source | Optional |

| 21 | Machine width/track length | 3000×8000 (mm) |

| 22 | Effective plate cutting size | 2000*6000 (mm) |

| 23 | Programming software | TubeMaster(2 Axis) |

| 24 | Mechanical accuracy | ±0.5 mm |

| 25 | Working interface | Chinese or English |

| 26 | Transfer method | USB/SD/RS232 |

| 27 | Cutting Gap Compensation | Automatic |

| 28 | Cutting torch lifting stroke (㎜) | 1-200mm |

| 29 | Cutting torch lifting distance | ≤200mm |

| 30 | Linear repeatability | ±0.5mm/1m |

| Motion Axis | Cutting machine axis selection | 2 Axis |

| X axis | Pipe rotation axis/ Plate lateral movement axis | ★ |

| Y axis | The torch moves along the length direction of the pipe/ Plate longitudinal movement axis | ★ |

| Z axis | Electric up and down | ★ |

3.2 Technical Index of cnc plasma cutter for sale ● Number of control axis: 2-axis linkage (three-axis or four-axis can be customized) ● Control accuracy: ±0.001mm ● Coordinate range: ± 99999.99mm ● Maximum pulse frequency: 200 KHz; Maximum operating speed: 15m/min ● Maximum number of program lines: 80,000 lines ● The largest single program: 4M ● Time resolution: 10ms ● System working power: DC +24V direct current power input, the power is greater than 80W. ● System working environment: temperature -10℃ to +60℃; relative humidity 0-95% non-condensing ● Maximum power of the drive THC increase motor: 45W (Note: only with T system). If you need more power, you can choose up to 200W. 3.3 System Interface of cnc plasma cutter for sale ● DB15 core male two-axis motor drive interface ● DB25 core female head 16-channel photoelectric isolation output, the maximum reverse current is 300mA ● DB25 core male connector 16-channel photoelectric isolation input, the maximum input current is 300mA ● Built-in USB interface on the front panel, convenient for users to transfer cutting code ● Optional standard DB9 core male serial port RS232 interface 3.4 Hardware Configuration of cnc plasma cutter for sale ●Display: F2100BX, 7-inch 800*480 high-resolution 16 million colors color high-brightness LCD screen F2300AX, 10.4-inch 800*600 high-resolution 16 million colors color high-brightness LCD screen F2300BX, 10.4-inch 800*600 high-resolution 16 million colors color high-brightness LCD screen F2500AX, 15-inch industrial VGA high-brightness LCD screen F2500BX, 17-inch industrial VGA high-brightness LCD screen F2600X, no display, but supports standard VGA interface display ● Memory: 64M SDRAM ● User program space: 256M ● Main frequency: 400MHZ system main frequency ● USB: USB1.1 interface front, supports at least 16GB USB flash drive. ● Keyboard: PCB film keyboard ● Chassis: The all-steel structure is completely shielded, which can truly prevent electromagnetic radiation, anti-interference, and anti-static 4. Automatic Programming Nesting Software of cnc plasma cutter for sale

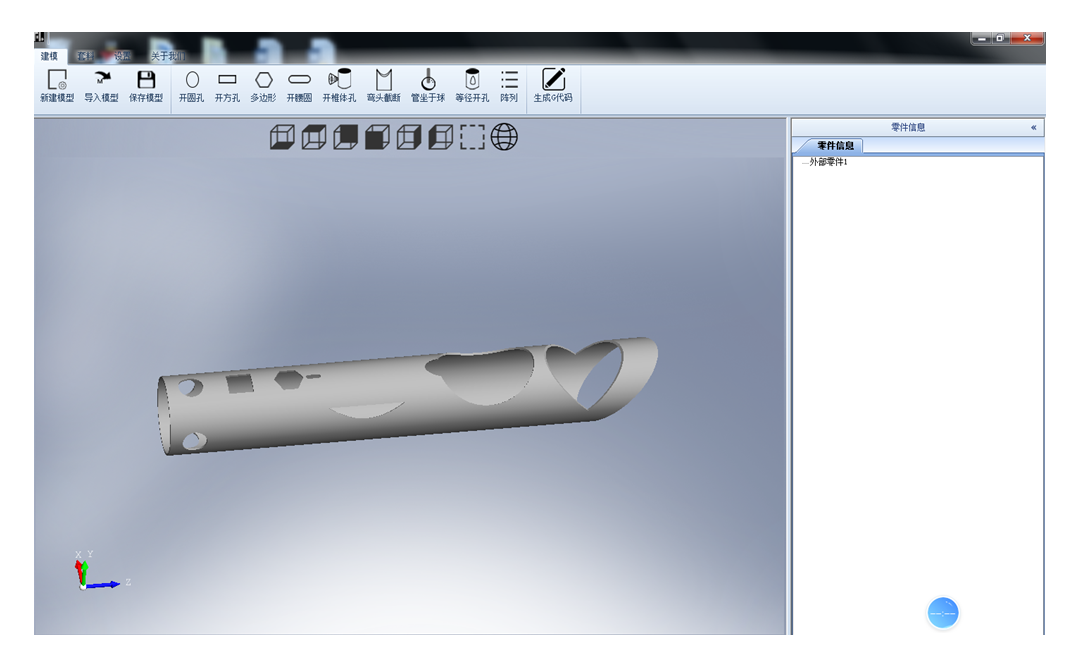

3.2 Technical Index of cnc plasma cutter for sale ● Number of control axis: 2-axis linkage (three-axis or four-axis can be customized) ● Control accuracy: ±0.001mm ● Coordinate range: ± 99999.99mm ● Maximum pulse frequency: 200 KHz; Maximum operating speed: 15m/min ● Maximum number of program lines: 80,000 lines ● The largest single program: 4M ● Time resolution: 10ms ● System working power: DC +24V direct current power input, the power is greater than 80W. ● System working environment: temperature -10℃ to +60℃; relative humidity 0-95% non-condensing ● Maximum power of the drive THC increase motor: 45W (Note: only with T system). If you need more power, you can choose up to 200W. 3.3 System Interface of cnc plasma cutter for sale ● DB15 core male two-axis motor drive interface ● DB25 core female head 16-channel photoelectric isolation output, the maximum reverse current is 300mA ● DB25 core male connector 16-channel photoelectric isolation input, the maximum input current is 300mA ● Built-in USB interface on the front panel, convenient for users to transfer cutting code ● Optional standard DB9 core male serial port RS232 interface 3.4 Hardware Configuration of cnc plasma cutter for sale ●Display: F2100BX, 7-inch 800*480 high-resolution 16 million colors color high-brightness LCD screen F2300AX, 10.4-inch 800*600 high-resolution 16 million colors color high-brightness LCD screen F2300BX, 10.4-inch 800*600 high-resolution 16 million colors color high-brightness LCD screen F2500AX, 15-inch industrial VGA high-brightness LCD screen F2500BX, 17-inch industrial VGA high-brightness LCD screen F2600X, no display, but supports standard VGA interface display ● Memory: 64M SDRAM ● User program space: 256M ● Main frequency: 400MHZ system main frequency ● USB: USB1.1 interface front, supports at least 16GB USB flash drive. ● Keyboard: PCB film keyboard ● Chassis: The all-steel structure is completely shielded, which can truly prevent electromagnetic radiation, anti-interference, and anti-static 4. Automatic Programming Nesting Software of cnc plasma cutter for sale  The software can now generate and cut the following types of pipe cutting nodes: Can arbitrarily generate the 3D model (step or stp format) of the pipe you need, including round pipe and square pipe. Generate various opening shapes, including round holes, square holes, polygons, notches, cone holes, truncated elbows, and special openings with equal diameters. The software supports the functions of adding lead-in lines, cutting compensation, spacing between parts, trajectory co-edge, and generating trajectory editing functions. After the nesting is finished, the software can directly display the nesting results (processing trajectory and cutting gun attitude), and the user can view the results at a glance. This software has the function of dynamic simulation cutting, which can dynamically simulate cutting the result of nesting, and users can intuitively watch the cutting situation. In this software, the user can maintain the raw material data by himself, and the raw material results after the nesting can be synchronized to the raw material database to facilitate the next cutting. This software can automatically generate G code files. This software can re-return a specific G code file to generate graphics. 5.THC Shanghai Fangling F1621 of cnc plasma cutter for sale

The software can now generate and cut the following types of pipe cutting nodes: Can arbitrarily generate the 3D model (step or stp format) of the pipe you need, including round pipe and square pipe. Generate various opening shapes, including round holes, square holes, polygons, notches, cone holes, truncated elbows, and special openings with equal diameters. The software supports the functions of adding lead-in lines, cutting compensation, spacing between parts, trajectory co-edge, and generating trajectory editing functions. After the nesting is finished, the software can directly display the nesting results (processing trajectory and cutting gun attitude), and the user can view the results at a glance. This software has the function of dynamic simulation cutting, which can dynamically simulate cutting the result of nesting, and users can intuitively watch the cutting situation. In this software, the user can maintain the raw material data by himself, and the raw material results after the nesting can be synchronized to the raw material database to facilitate the next cutting. This software can automatically generate G code files. This software can re-return a specific G code file to generate graphics. 5.THC Shanghai Fangling F1621 of cnc plasma cutter for sale  ● New operation panel design and color matching, upgrade the grade; optimize the follow algorithm to improve the cutting quality ● Push-down knob, clean and simple, easy to operate ● Using high-power arc starting relay to enhance the stability of arc starting ● Dual LED digital display, simple and clear ● Newly added dynamic perforation knob, convenient for real-time change of parameters, to achieve better cutting effect. 6.After-sale Service (1) After check and acceptance by clients, the warranty period is 1 year. (2) During 1-year warranty period, Yomi provides free repair service in case of failure due to defective part/ component, and replaces defective part or component free of charge. Transportation costs are borne by clients ,such as express fees. (3) During the 1-year warranty period, when we get maintenance call ,we will reply within 8 hours, and set up a 1:1 chat group on WhatsAPP or QQ to follow-up, through video and Computer remote control etc, guide the customer to solve the fault or replace accessories. If clients need on-site repair, Yomi will arrange the overseas engineer ( usually 1 person ,can speak English) immediately; the traffic, Visa, air ticket, food, accommodation, translation, internet, overseas allowance etc for Yomi engineer should be borne by clients. (4) After the warranty period, the replacement parts will be charged at the cost price. Transportation costs are borne by clients, such as express fees/air costs. (5) Controller system and sofware will be upgraded free of charge. (6) Except for human damage for machine, Yomi supply life-long maintenance service. 7. Customer Using Case of cnc plasma cutter for sale

● New operation panel design and color matching, upgrade the grade; optimize the follow algorithm to improve the cutting quality ● Push-down knob, clean and simple, easy to operate ● Using high-power arc starting relay to enhance the stability of arc starting ● Dual LED digital display, simple and clear ● Newly added dynamic perforation knob, convenient for real-time change of parameters, to achieve better cutting effect. 6.After-sale Service (1) After check and acceptance by clients, the warranty period is 1 year. (2) During 1-year warranty period, Yomi provides free repair service in case of failure due to defective part/ component, and replaces defective part or component free of charge. Transportation costs are borne by clients ,such as express fees. (3) During the 1-year warranty period, when we get maintenance call ,we will reply within 8 hours, and set up a 1:1 chat group on WhatsAPP or QQ to follow-up, through video and Computer remote control etc, guide the customer to solve the fault or replace accessories. If clients need on-site repair, Yomi will arrange the overseas engineer ( usually 1 person ,can speak English) immediately; the traffic, Visa, air ticket, food, accommodation, translation, internet, overseas allowance etc for Yomi engineer should be borne by clients. (4) After the warranty period, the replacement parts will be charged at the cost price. Transportation costs are borne by clients, such as express fees/air costs. (5) Controller system and sofware will be upgraded free of charge. (6) Except for human damage for machine, Yomi supply life-long maintenance service. 7. Customer Using Case of cnc plasma cutter for sale  8. Cutting Sample of cnc plasma cutter for sale

8. Cutting Sample of cnc plasma cutter for sale