Summary information:

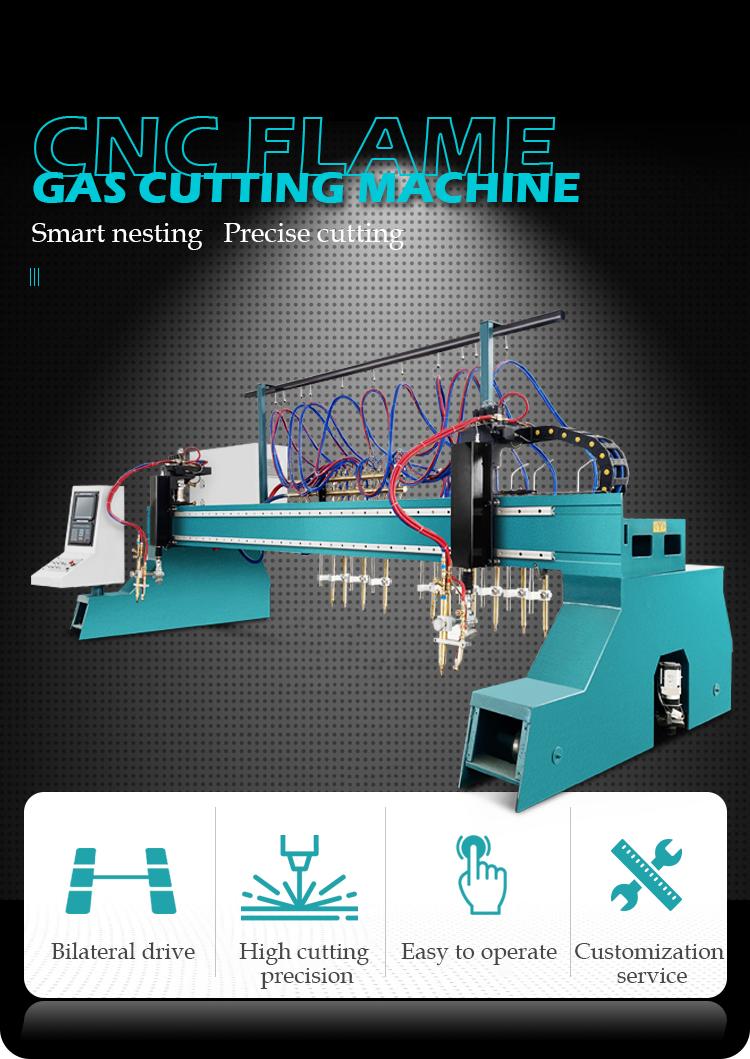

Multi torch straight strip cnc plasma cutter price is characterized of stable running and high efficiency, can be widely applied for strips cutting of carbon steel, manganese steel and other materials.

1. Multi torch straight strip cnc plasma flame cutting machine is suitable for the steel industry or make steel straight cutting relatively large amount of users.cnc plasma cutter price is very reasonable.

2. Straight torch choice is based on the number of torches used steel straight cutting width and the minimum size to choose.3. Multi torch straight strip cnc plasma flame cutting machine can be made in front of CNC contour cutting back straight cutting multi-purpose functionality. cnc plasma cutter price is very competitive.

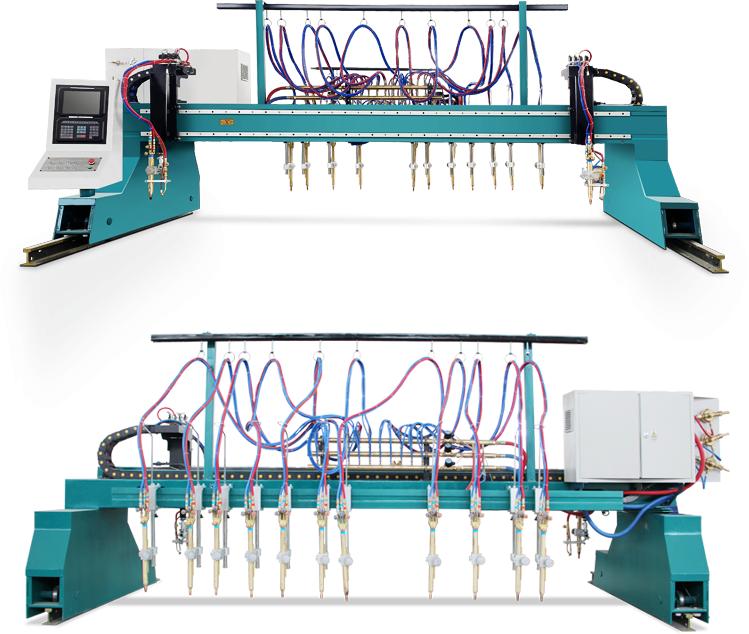

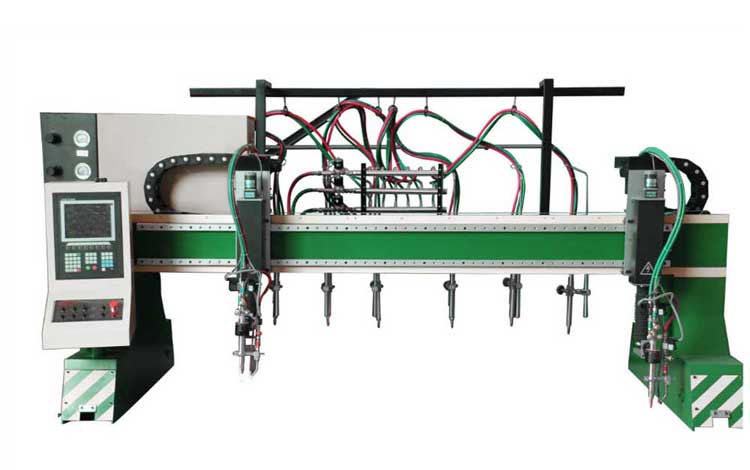

Multi torch straight strip cnc plasma flame cutting machine’s frame use gantry structure, bilateral drive to improve cutting quality. Host N Group front torch for longitudinal straight cut back a set of lateral torch for straight cuts, improve cutting efficiency. Multi torch straight strip cnc plasma flame cutting machine can configure torch number, longitudinal and transverse cutting configured according to user needs, can be cut more once to walk one time.| Model | Multi-torches CNC Cutting Machine |

| Cutting area | 3.15*8m(can be customized) |

| Machine size | 4*10m(according to customers’ needs) |

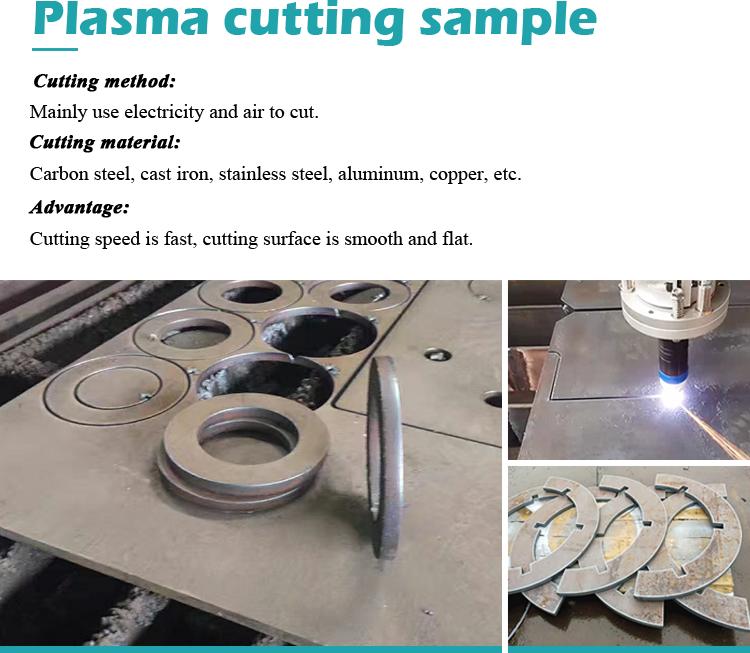

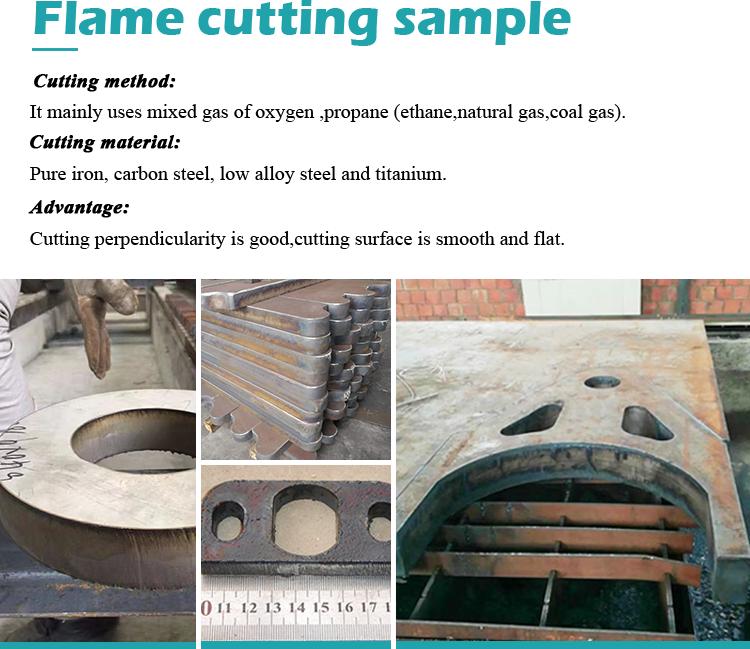

| Cutting method | Flame/Plasma |

| Cutting thickness | Flame cutting: 6-150mmPlasma cutting: according to plasma power |

| flame cutting speed | 20-700mm/min |

| Ignition mode | Automatic ignition |

| Plasma cutting speed | According to plasma power |

| Plasma torch anti-collision protection system | Yes |

| Driving method | Servo or stepper |

| Software | Starcam |

| Working condition | |

| Working pressure of compressed gas | >7Mpa |

| Required gas flow of plasma | 4500L/H |

| Working environment | Ventilation, no concussion |

| Power voltage | 5KW(not include plasma power) |

| Types of gas | Acetylene Propane |

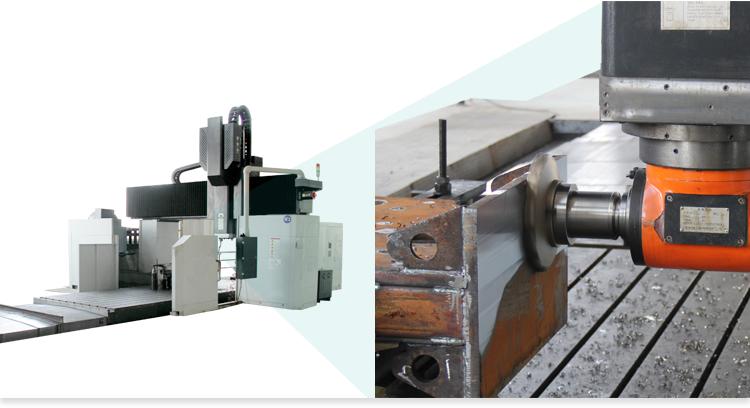

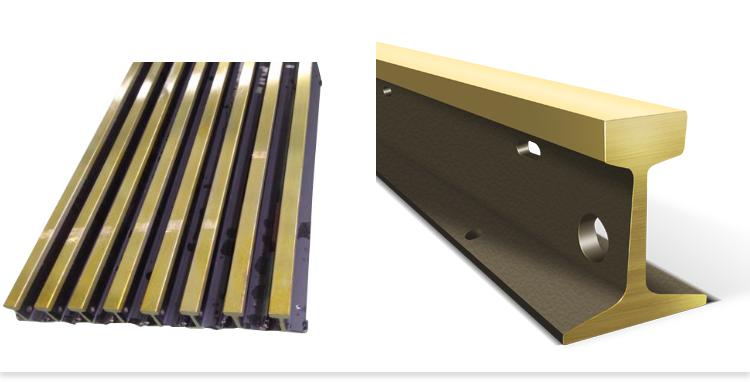

Heavy gantry structure

Bilateral drive, beam adopts plate tube welding structure

Hollow steel plate welded frame

Facilitate heat dissipation and prevent thermal deformation. The machine body is shot blasted and sprayed with a long service life.

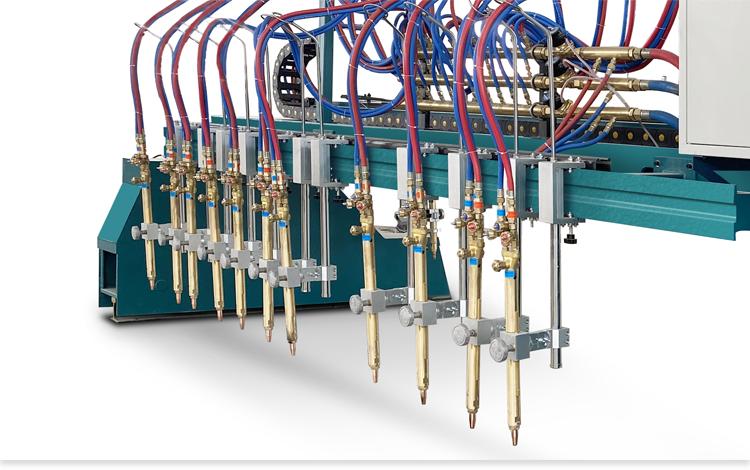

Multiple sets of straight cutting torches

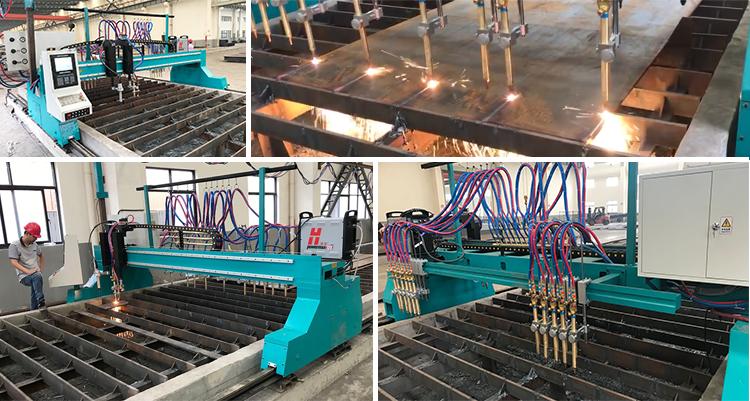

This machine is mainly used in steel structure industry. It can be equipped with multiple sets of straight cutting torches to cut steel plate into structural parts required by steel structure. It has features of fast cutting speed, high efficiency and less deformation.

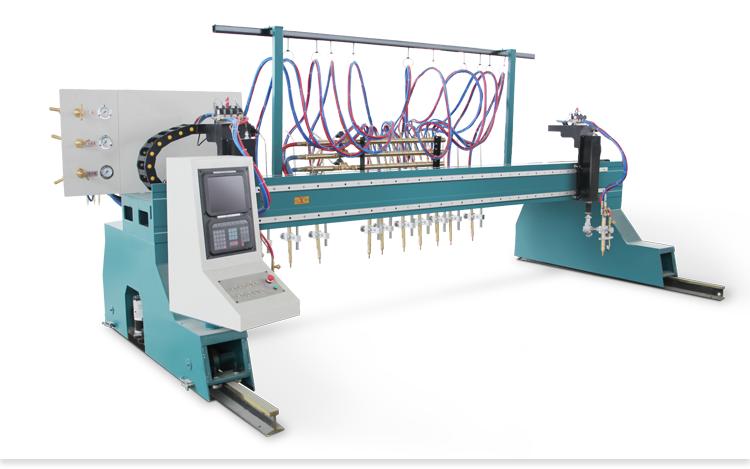

Shanghai Fangling 2300B System

10.4 inch LCD screen, high integrated motherboard material, good stability

Automatic programming nesting software

Without basic knowledge, customers can easily load DXF graphics into the software. Or use our integrated CAD-system STAR CAMCad to create graphics. Process data will be automatically generated through CNC CUT graphics. The software will also provide the best processing path, and this processing path can be changed at any time as required

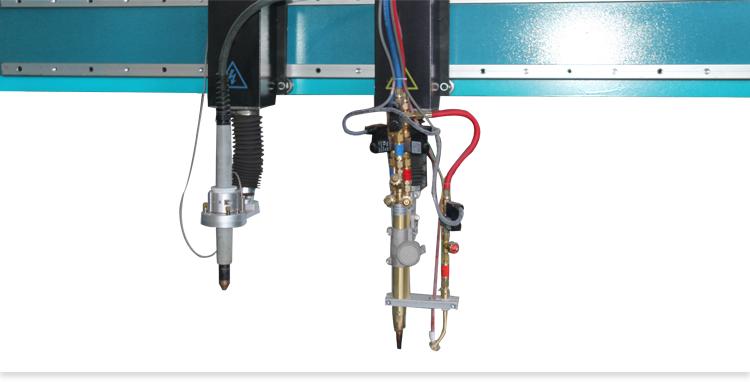

Automatic electronic ignition and configurable capacitor height controller

The automatic ignition adopts ignition needle type, which greatly extends the service life, high degree of automation, reduces the labor intensity of workers, improves safety, and the advantages of multiple cutting torches are more prominent.The capacitor height controller ensures that the cutting torch and plate maintain a certain height, the operation is convenient for workers, and the service life of cutting nozzles are prolonged.

Optional plasma and flame cutting method

Choose suitable cutting method according to material and thickness.

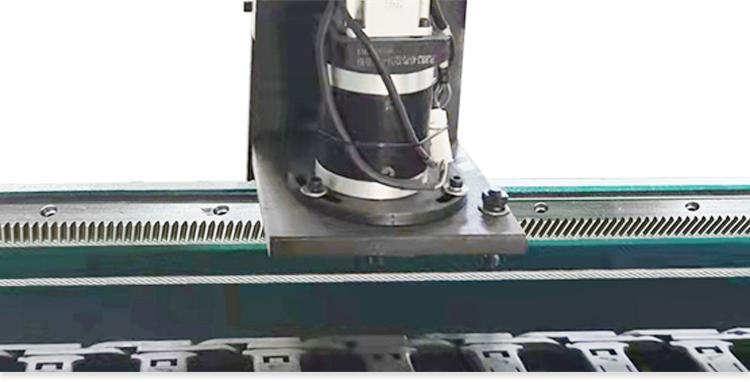

High precision rack and gear

High transmission accuracy, smooth cutting operation

Gantry milling finished

The machining center completes one-time milling and the accuracy is within 0.02mm

24KGS heavy-duty high-strength heat-treated guide rail

High precision, strong load carrying capacity

Customer Site Display Packing&Shipping

Packing&Shipping  Company Introduction

Company Introduction After Sales Service

1. One year warranty for whole machine 2. We have experienced after-sales service team,we can send installation video or file to customers and guide installation for easy operated machines and we can also arrange our engineers to visit customer's site for installation and training for complicated machines. 3. Full stock of spare parts and consumables are at competitive price.ottles in all shapes.

FAQ

1. What kinds of after-sales service can your company supply? One year's warranty for whole welding machine. We will send spare parts for free during warranty period. About main board, we can supply life long service. 2. Can you supply OEM Service? Yes, we can supply OEM service. 3. What is deliver time? We will delivery the goods within 15-20 work days after received payment. 4. What is your payment term? We can accept T/T,Western Union,L/C,Aliexpress Escrow, Credit Card.